FEM and OptoPhi analysis

Know and obtain crucial information on the performance and reliability of a technical solution, identifying its strengths and critical points even before the prototype takes shape.

ADVANTAGES FOR YOUR COMPANY

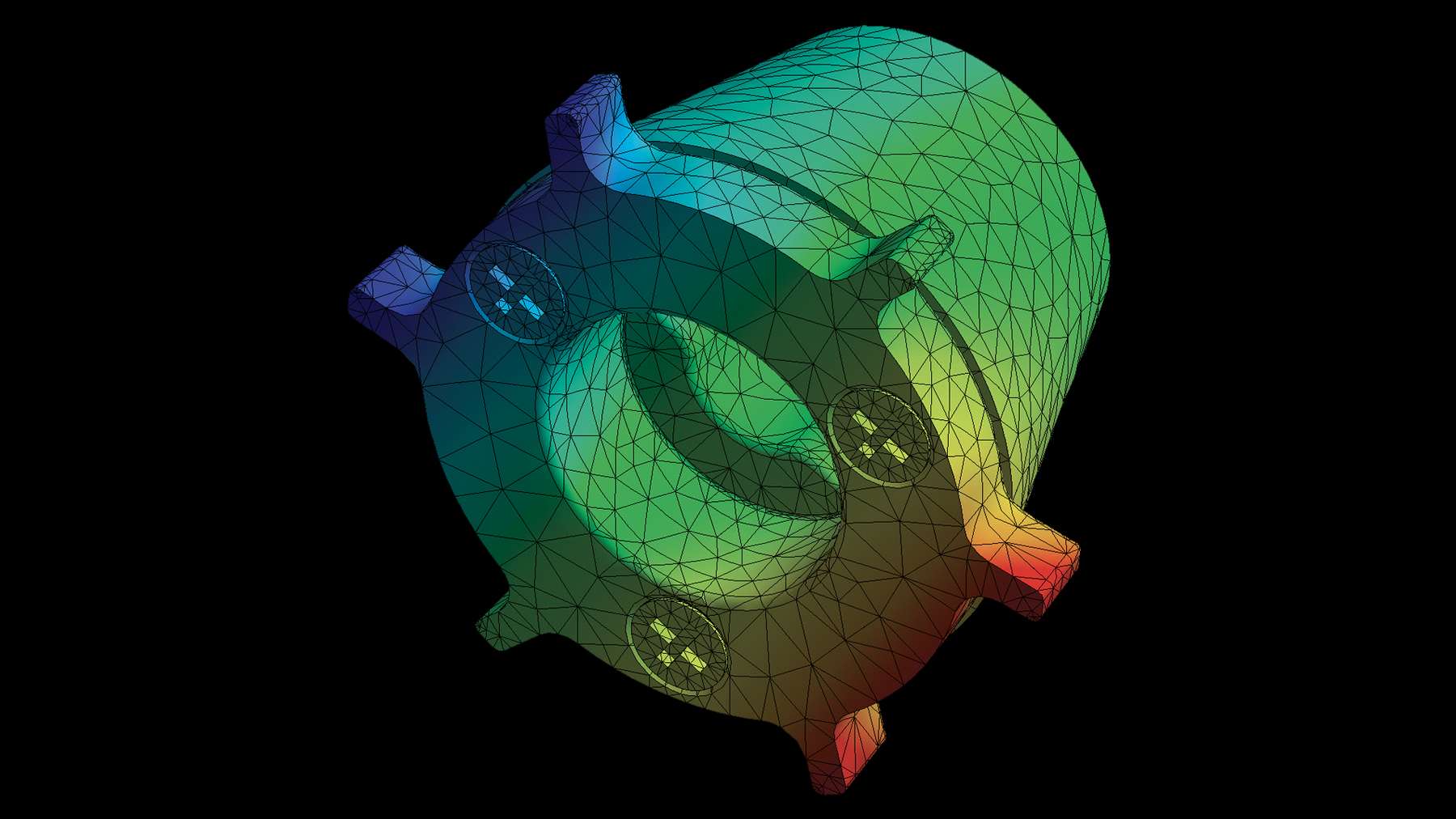

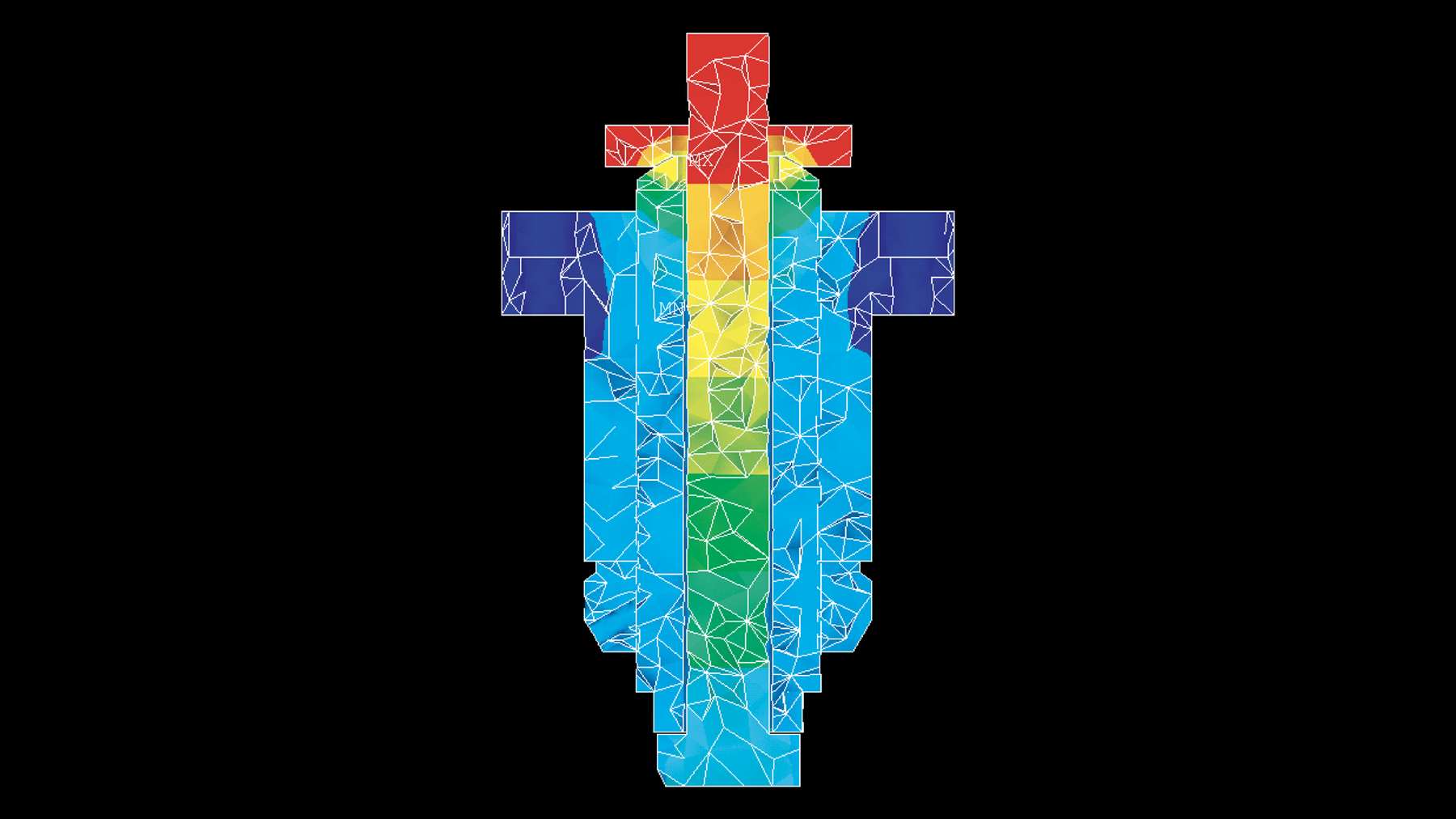

FEM Analysis (Finite Element Analysis) deserves a special mention because it represents a cutting-edge tool capable of simulating displacements, temperatures, stresses, deformations, electric or magnetic fields and all the variables that can positively or negatively impact the performance of an instrument and / or of a component.

This means being able to simulate particular conditions to be able to identify critical points of the structures, excess or defect of material, correct distribution of the masses, states of deformation and breaking points.

Identifying any critical issues and providing the information needed to solve them (with OptoPhi) makes FEM analysis a valuable tool at any stage, from the development of a product to the optimization of existing projects through the analysis of manufacturing processes and the diagnostics of system failure points.

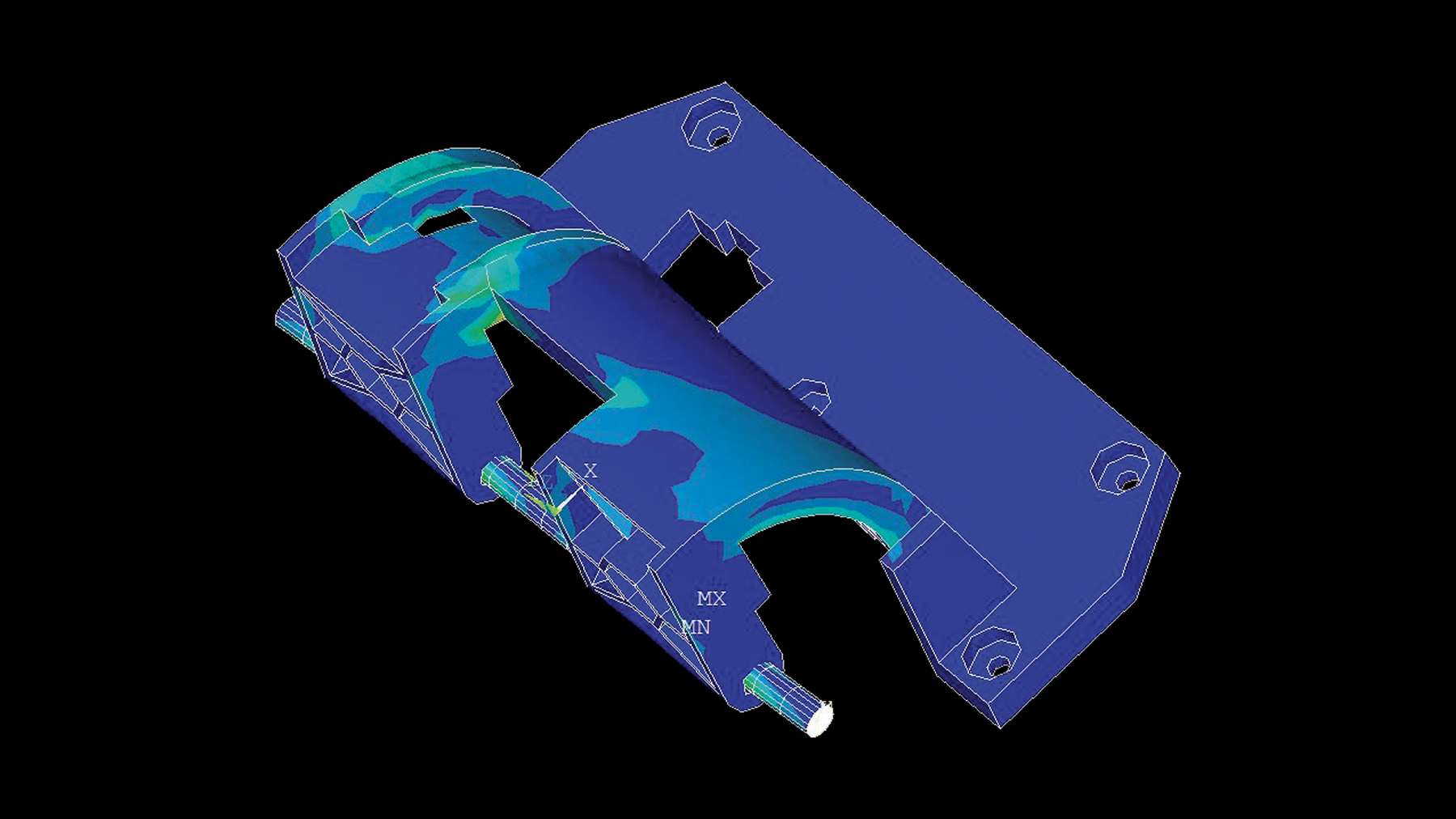

Once the critical points and weak points have been identified with the FEM analysis, it is time to intervene with tools that optimize the project.

OptoPhi is a highly automated tool for mechanical and electromechanical application that, in close interaction with FEM analysis, is able to identify the best design solution and increase the performance even of consolidated objects in the order of 10-20%.

group contacts